Технологии

Машиностроение общего назначения

[General machinery industry] Machining solution to plunger pump cylinder

Industrial Machining Introduction

The plunger pump, a key device of the hydraulic system, changes capacity of sealing cavity through reciprocating motion of the plunger in the cylinder to realize oil suction and pressing. It is widely applied to occasions with high pressure, heavy flow and flow regulation requirement, for instance, hydraulic machine, engineering machinery, ship and other fields.

Main parts of the plunger pump include cylinder, plunger, oil distribution tray, return tray, sliding shoe, spherical hinge and transmission shaft, featuring numerous parts, complex machining and high requirements for machining accuracy and surface quality. Main materials include 38CrMoAl, 42CrMo and 40Cr of which 38CrMoAl material belongs to senior nitrated steel with high abrasive resistance, fatigue strength and strength, poorer mechanical machining property and high requirement for comprehensive cutter property. Xiamen GESAC has mature process solutions for these main parts. And process solution to plunger pump cylinder is highlighted here.

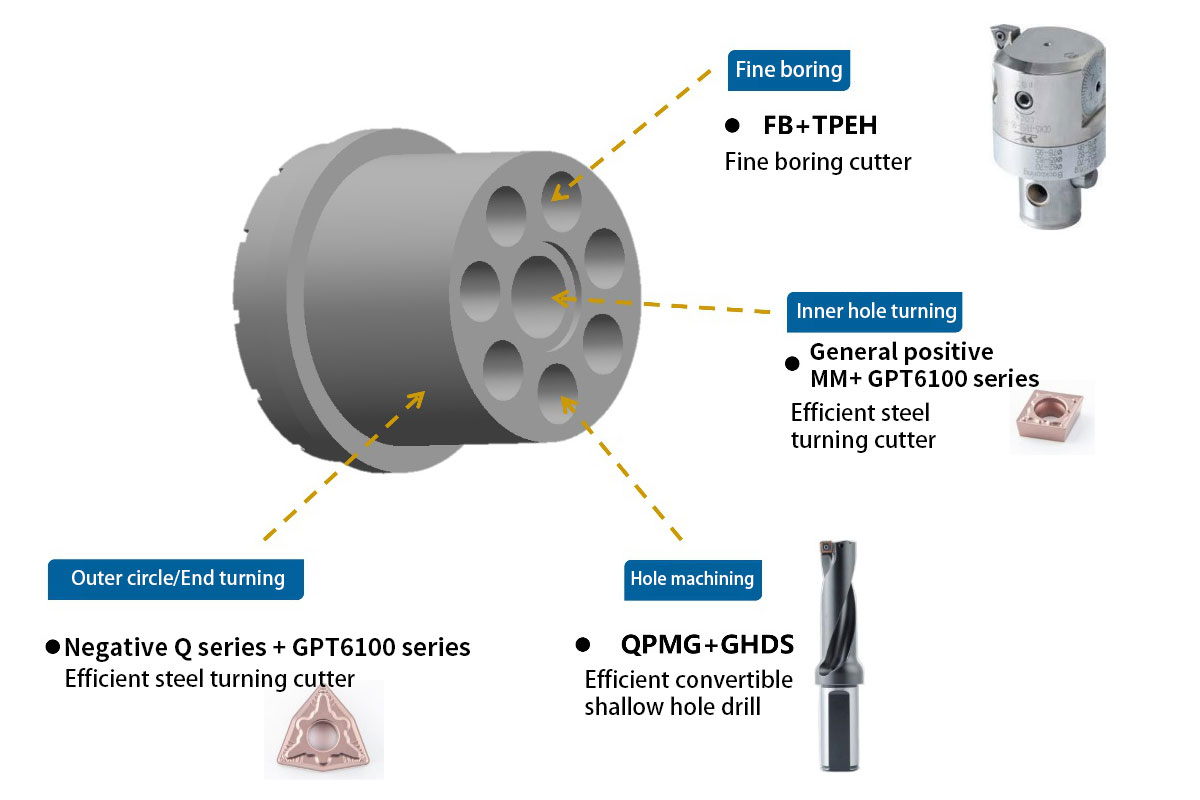

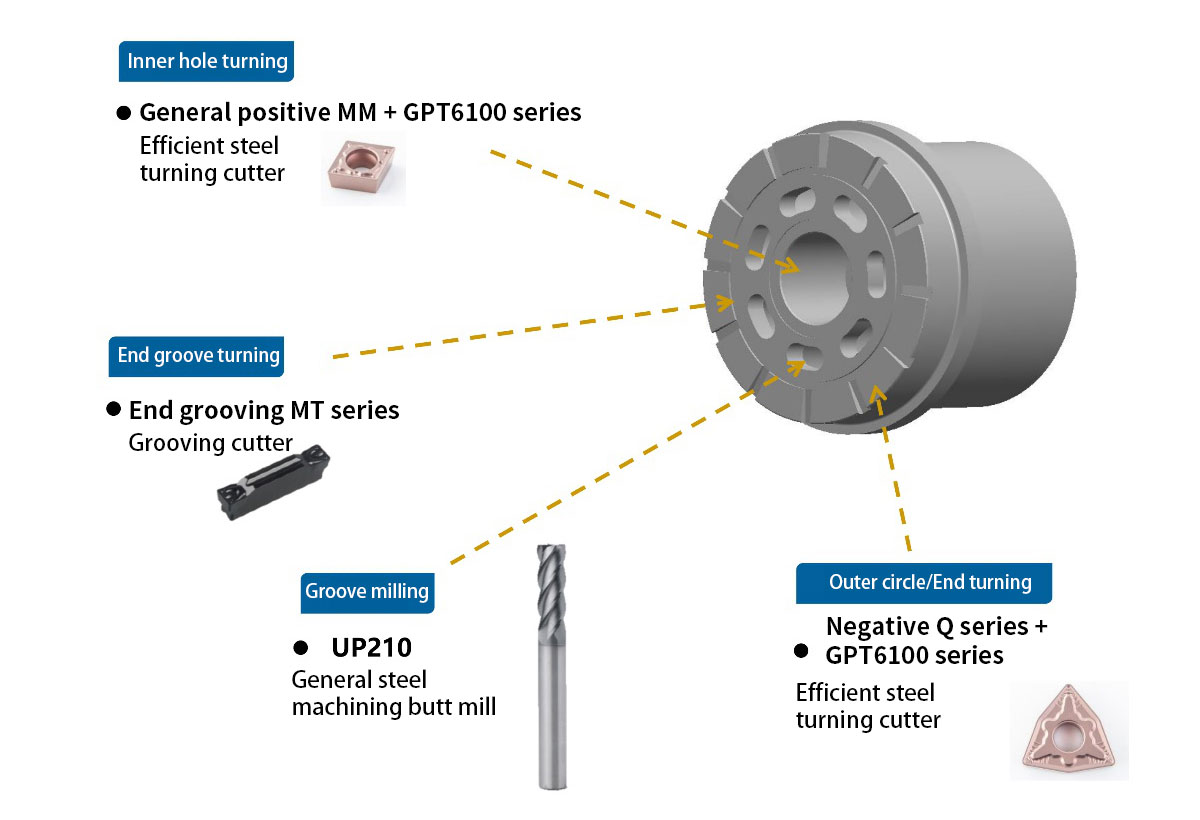

Integrated machining solution to plunger pump cylinder

Application Characteristics

With unique GE.FORCE technology, it makes blades have higher abrasive resistance and tenacity through merging rigid surface layer, high tenacity coating technology and advanced post-treatment technology and matching with special rigid alloy base. Its product arrays include GPT6110, GPT6120 and GPT6130 grades, matching with negative Q series and positive MM series groove types. Its application scope covers rough to fine machining working conditions.

--GPT6110: continuous high speed fine machining for carbon steel and low alloy steel

--GPT6120: medium and high speed semi-fine to fine machining for carbon steel and alloy steel

--GPT6130: medium speed rough to semi-fine machining for carbon steel and alloy steel

--Machining mode: outer circle, end, inner hole and shape turning--Recommended cutting speed: Vc=200~350 m/min

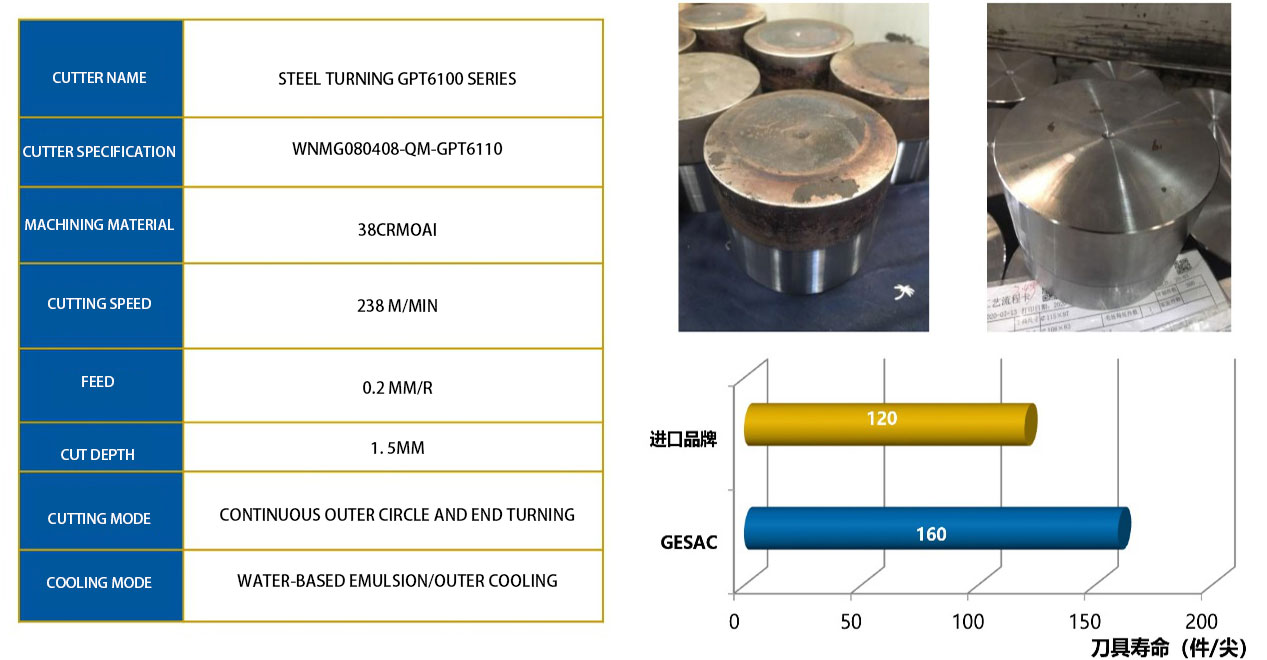

Typical Case

Outer circle and end turning of plunger pump cylinder. Under the same working condition, our QM+GPT6110 combination improves service life by about 30%, comparing with that of similar cutters from imported brands.

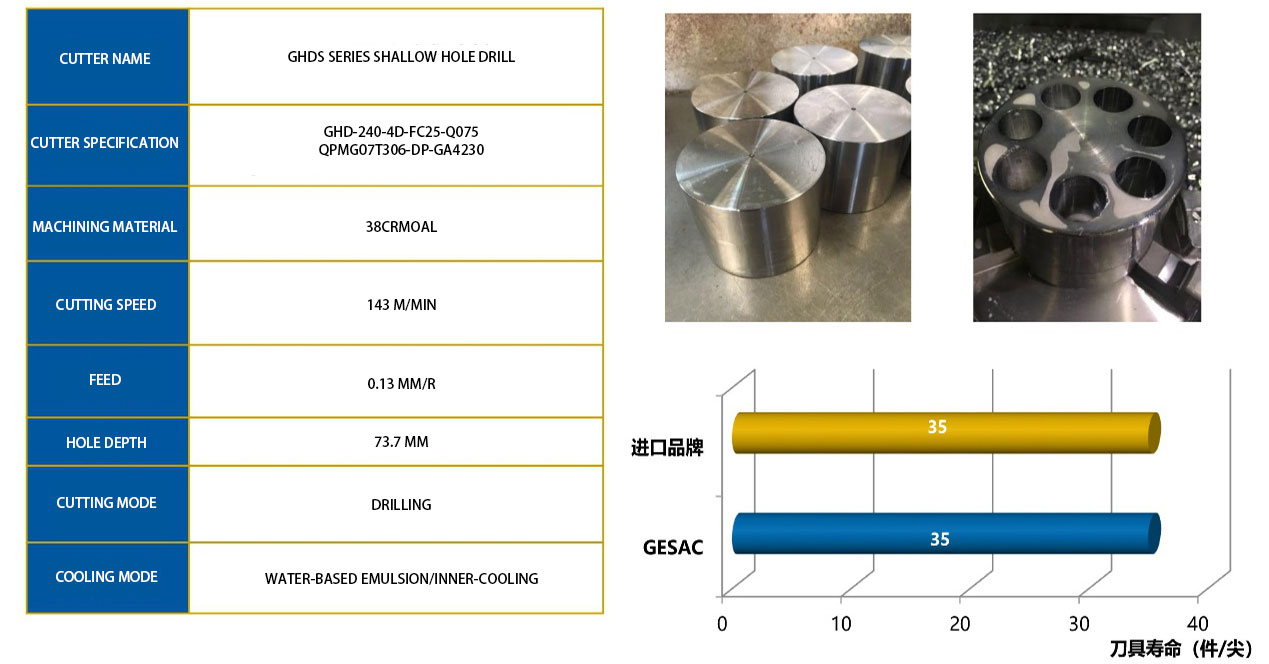

GHDS Dual-Spiral Inner-Cooling Shallow Hole Drill

With dual-spiral inner-cooling structure design, it has higher cutter body strength and good chip removal property, and its product arrays include 2 to 5 times of diameter. Cutter diameters range from Ø14 mm to Ø40 mm and products have complete series.

Application Characteristics

--Machining material: general materials such as steel, stainless steel and cast iron

--Machining parts: flange, valve, cylinder, tube plate, steering knuckle and connecting rod

--Machining accuracy: IT12~IT13

Typical Case

Hole drilling of plunger pump cylinder. Under the same working condition, our GHDS cutters have equivalent property as that of similar cutters from imported brands on the market.