Technology

Medical Industry

[Medical industry] Machining solution to dental crown

Industrial Machining Introduction

With improvement of Chinese people's living standards, more and more people start to pay attention to beauty and health of teeth. Relevant market of tooth implant and repair is growing.

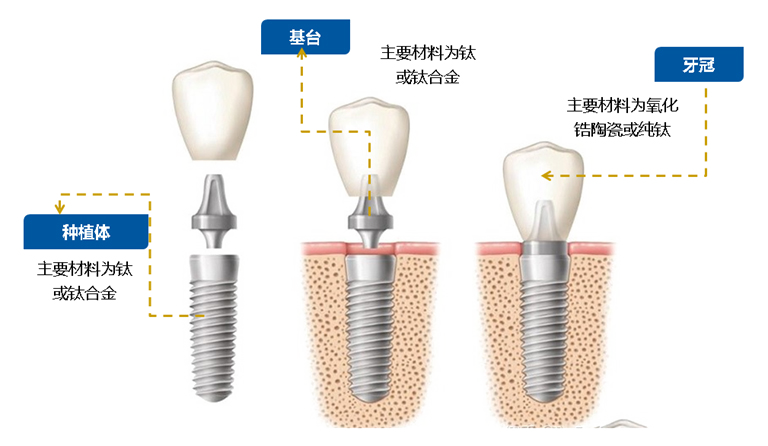

Tooth Implant System

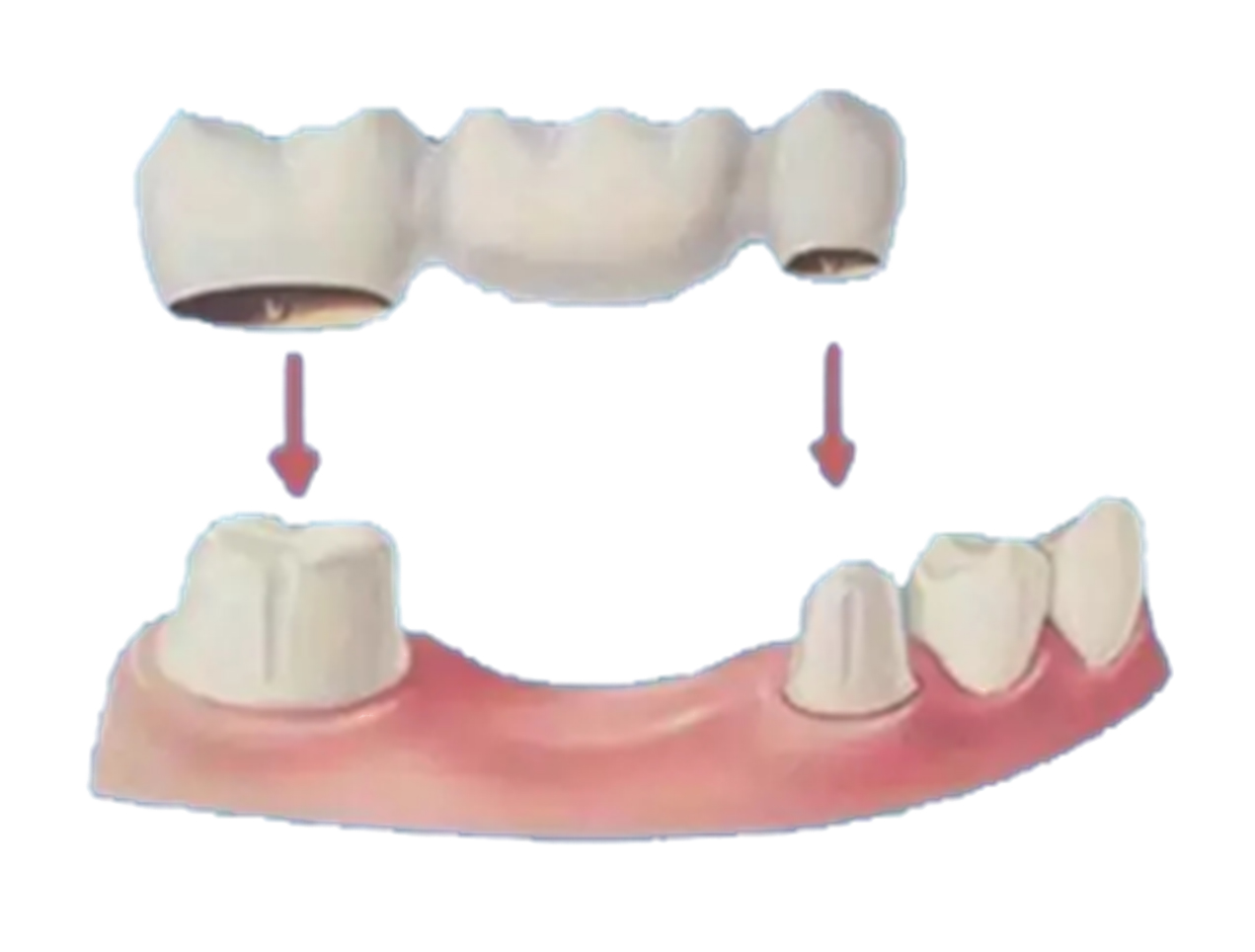

There are 3 major common agomphosis repair modes currently, i.e. moving denture, fixed denture and implanted teeth.

Commonly known as false tooth, the moving denture (professionally known as removable denture) includes removable partial and complete denture. It is supported by remaining natural tooth, base and bone tissue, and fixed by retainer and base of the denture, featuring convenient substitute and poorer stability.

The fixed denture is the prosthesis of one or several missing teeth in the repair dentition. It holds the missing tooth through grinding healthy teeth at both sides of the missing tooth to become a "pier". Since the prosthesis cannot be worn by a patient independently, it is known as the fixed denture. It is also known as fixed bridge due to its similar structure as a bridge. It is comfort and stable, with high requirements for adjacent teeth.

The implanted tooth consists of implant, implant base and dental crown. The implant is fixed to a tooth jaw in "synostosis" mode to serve as artificial tooth root before connecting with the upper dental crown through the base to perform its function. The implanted tooth features stability, harmless to adjacent teeth, comfort and long utilization time, comparing with two tooth repair modes above.

Implanted tooth-dental crown production equipment

Dental crown of an implanted tooth is mainly produced by special dental machining equipment. The common oversea brands include ROLAND, IMES, VHF, WIELAND and AMANN; common domestic brands include Shenzhen Xiangtong, Shenzhen Cradle, Shanghai Shendiao and Chongqing Zhuotian.

Roland

IMES-ICORE

VHF

Xiangtong

Cradle

Product Characteristics

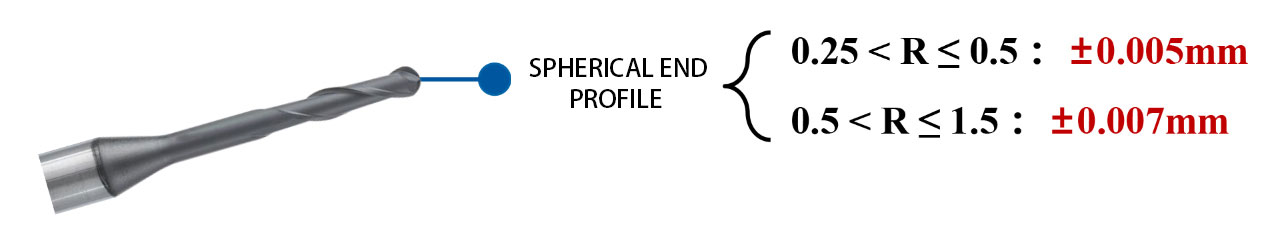

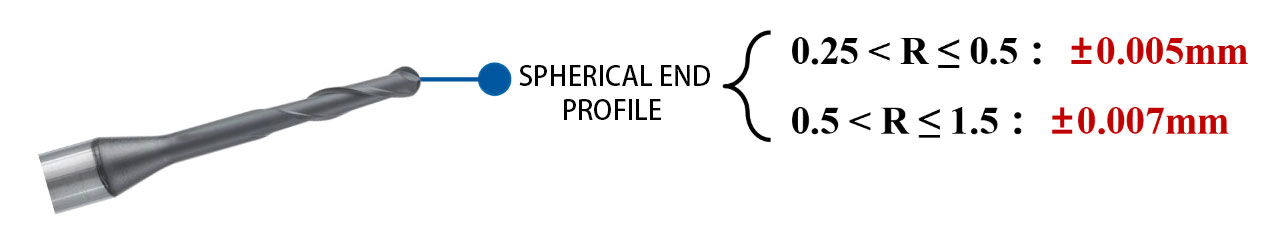

1. High accurate spherical end profile and product stability

SM200 series two-blade long neck spherical end butt mill with diamond coating

SM200 series two-blade long neck spherical end butt mill with coating

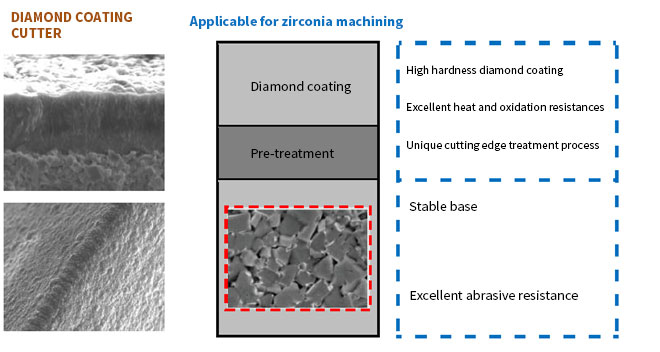

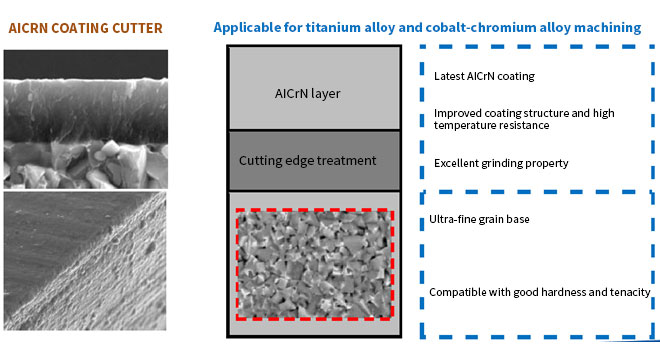

2. Applicable for zirconia and titanium alloy machining

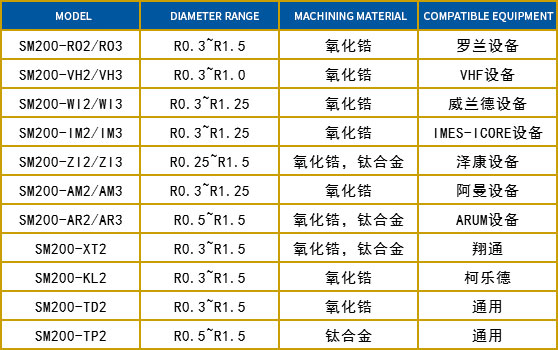

3.Able to meet demands of several equipment

Application Case

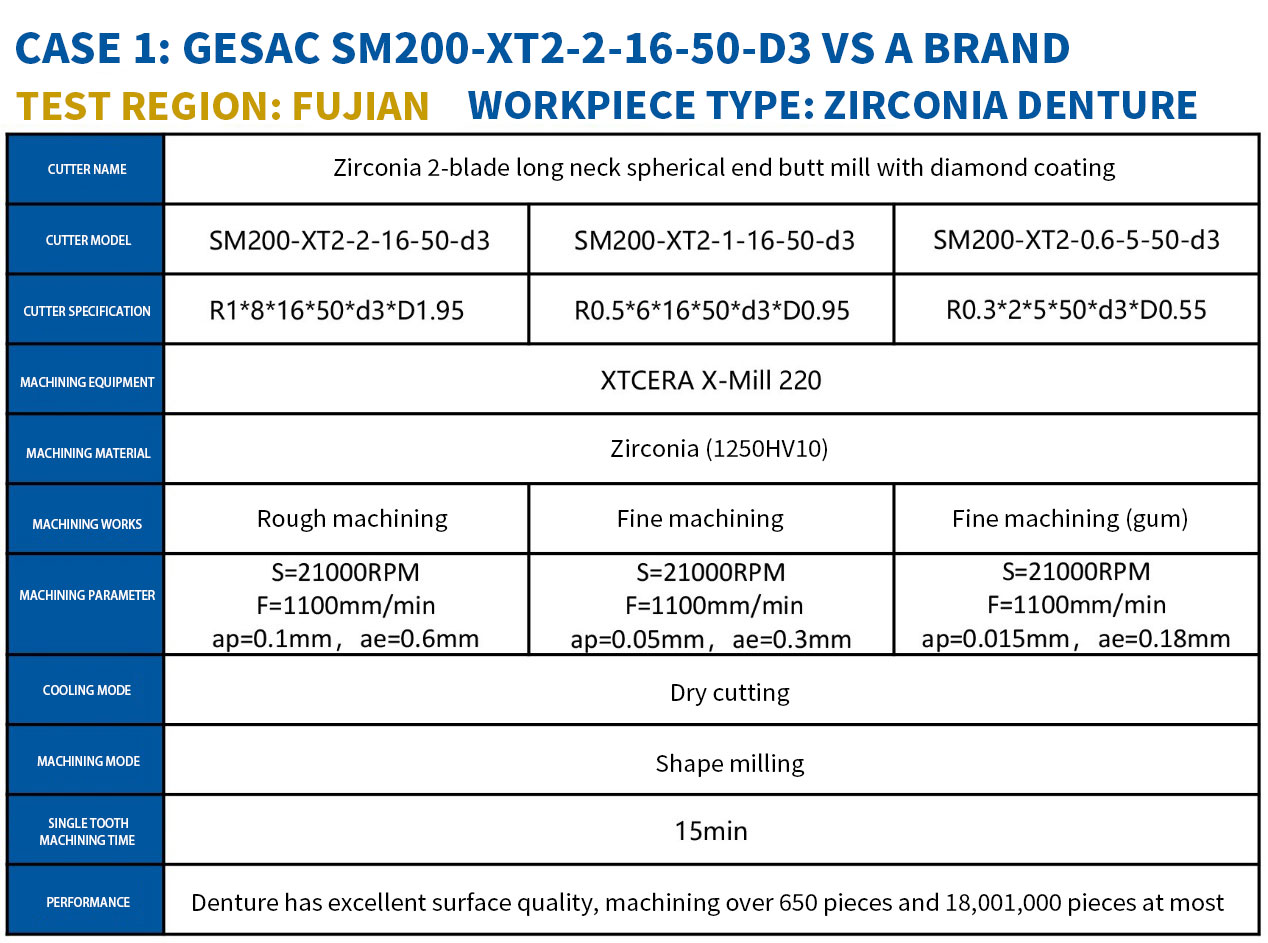

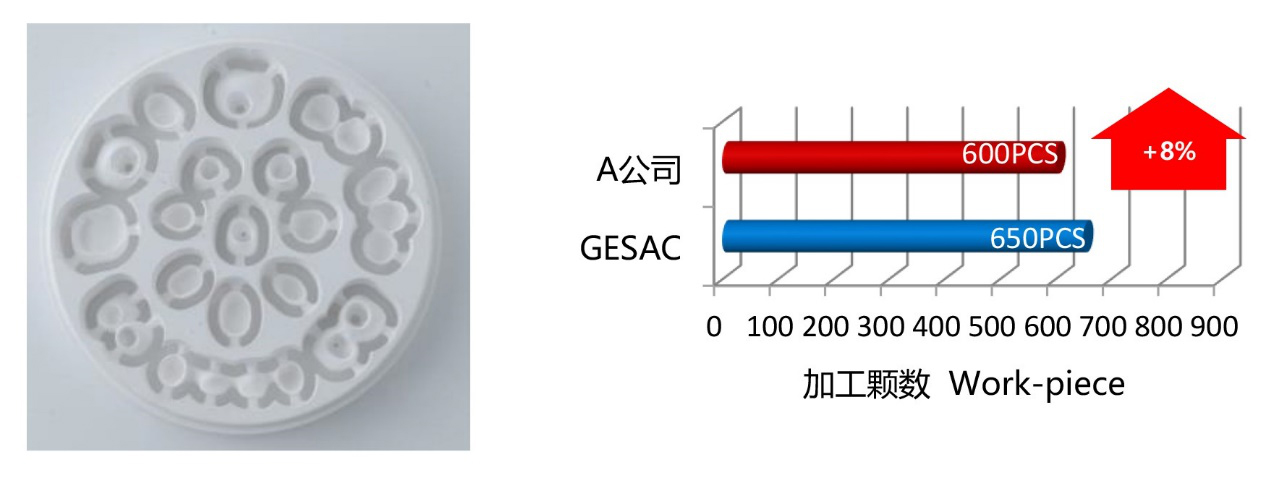

The case is the machining case of zirconia rough. Under the same working condition, SM200 series two-blade long neck spherical end butt mill with diamond coating improves its service life by 8%, comparing with that of the cutters from Company A (a competitor).

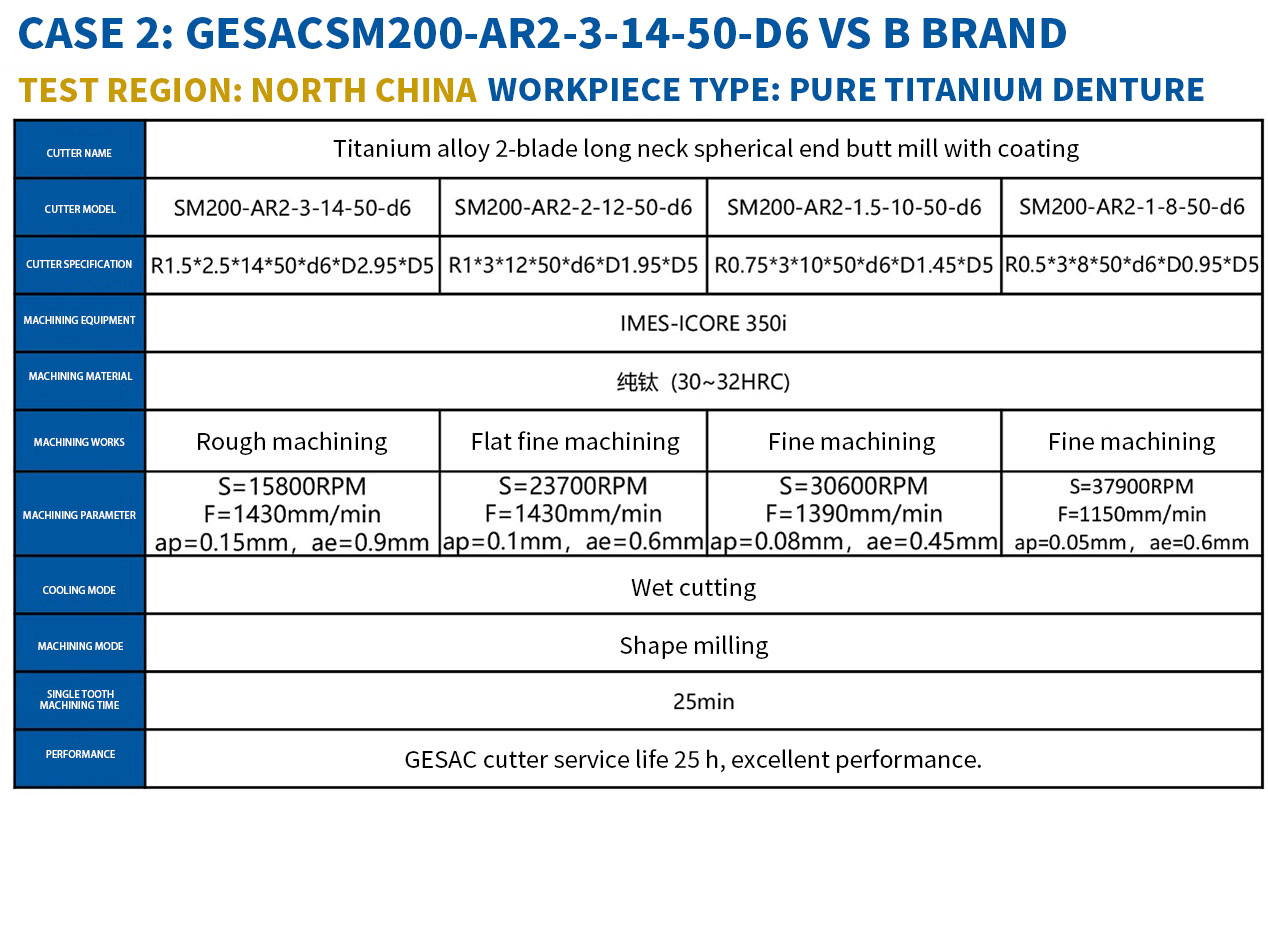

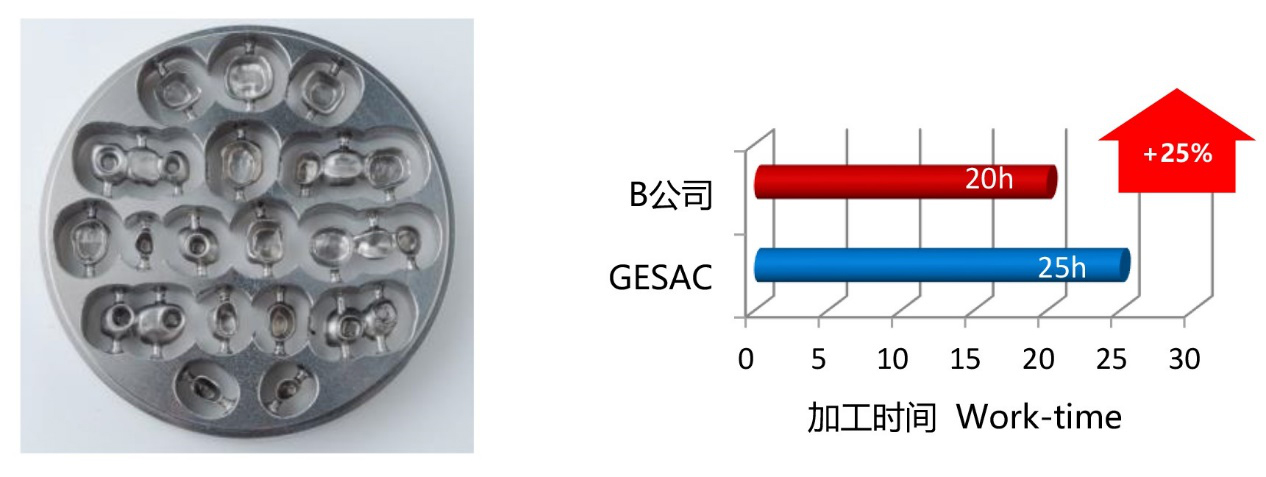

The case is the machining case of titanium rough. Under the same working condition, SM200 series two-blade long neck spherical end butt mill with coating improves its service life by 25%, comparing with that of the cutters from Company B (a competitor).